Forging Greener Steel

Among its long-term environmental targets called “Hitachi Environmental Innovation 2050,” Hitachi has set a target to achieve carbon neutrality throughout its value chain by fiscal 2050 in order to help build a decarbonized society. This means that every product Hitachi produces must be carbon neutral, right down to the screws and sheet metal that encase our products. Of course, Hitachi is a heavy user of steel; we make everything from data storage systems and refrigerators to high-speed bullet trains. So, it only made sense that we would take a more sustainable approach to producing steel.

The production of steel has been a very carbon intensive process from the beginning – not only using coal to create the intense heat that is required to melt the iron ore, which is in the form of ferric oxide F2 O3, but also to transform it into steel. The steel making process causes the iron, or ferric oxide, to release its bond with the oxide molecules, causing the oxygen to bond with the carbon in the coal to form carbon dioxide, CO2, which is released into the environment. The problem is that making 1 ton of steel produces about 1.85 tons of CO2, according to CarbonClean. In 2018, the world produced about 1.8 billion tons, or a whopping 3.3 billion tons of CO2 emissions.

Fortunately, there are greener ways to purify iron. Instead of using carbon to remove the oxygen from ore, we can use hydrogen, creating H2O – water. However, to make truly green steel, the creation of the hydrogen must also be green. Today the cheapest way to create hydrogen is done by heating natural gas, mostly methane, CH4, but this process creates a lot of CO2. The process of using methane as the feedstock to produce one ton of hydrogen may create 9 to 12 tons of CO2. Hence, the need to create “green” hydrogen.

Green hydrogen can be produced through the electrolysis of water, as long as the energy for generating the electricity comes from non-fossil fuels, like wind, solar, hydro or nuclear. And in order to be viable, the cost of the electrolysis of water must be competitive to the cost of the methane process of creating hydrogen.

In July 2022 Hitachi Energy announced that it has signed a Memorandum of Understanding (MoU) with H2 Green Steel, a Swedish Industrial startup to leverage electrification, digitalization, and hydrogen to support the decarbonization of the steel industry. H2 Green Steel plans to eliminate almost all carbon dioxide (CO2) emissions from the steel production process by using hydrogen instead of carbon and is planning to build its first fossil free steel plant in Boden, Sweden. Alongside the steel plant will be a giga scale electrolyzer plant to produce green hydrogen from water for the hydrogen reduction of Iron.

Starting with the plant in Boden, Sweden, H2 Green Steel will leverage Hitachi Energy's IT and OT capabilities to optimize the value chain to plan, build, operate, and maintain the power infrastructure to reduce costs and optimize the process. The steel production in Boden will use green hydrogen instead of coal in a fully integrated process using end-to-end digitalization, which reduces up to 95 percent of CO2 emissions compared to traditional steelmaking at a lower cost. Since other companies in Europe are committed to carbon neutrality in their supply chain by 2050, the demand for green steel is expected to be very strong.

“Achieving carbon-neutrality globally requires efforts from all industries to speed up the energy transition through collaborations,” says Johan Söderström, Head of Europe, Middle East and Africa at Hitachi Energy. “This collaboration with H2 Green Steel is a pioneering example of how we are working together and creating additional benefits for our customers. We are supporting H2 Green Steel's electrification project and at the same time, we are able to secure green steel for our products, which is in line with our Purpose “Advancing a sustainable energy future for all.”

Green Steel will represent a major link in Hitachi’s carbon neutral value chain over time. But it’s a process. And it starts with leveraging green energy to create the green electricity, which in turn creates green hydrogen, which can be used to create green carbon-free steel. Because of development and investments like these, the future of our manufacturing is bright with greener products, from storage systems to bullet trains, on the horizon.

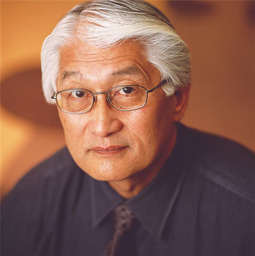

Hu Yoshida spent 24 years at Hitachi Vantara helping define technical direction and enabling customers to address their digital transformation needs. He is widely known in the industry and was instrumental in evangelizing Hitachi's unique approach to storage virtualization.