How to Disrupt the Disruption in Manufacturing Supply Chains

The past two years will get plenty of blame for supply chain disruption, but disruption — from human and technology error to weather and other crises — has always been a challenge. Manufacturers are using dashboards to visualize performance measurements to gain deeper diagnostics for uses like preventative maintenance and process optimization. But while they are a critical starting point, supply chain dashboards are not enough. Today’s manufacturers need a way to move from data collection through the supply chain to decision support and actionable insights.

In his supply chain management research, MIT Professor Yossi Sheffi noted that those companies that thrive and survive amid supply chain disruption bring people together in control centers creating a “plan B” for when disruption occurs, and a centralized area of focus for data and insights. Track and trace solutions build on the control tower concept to bring manufacturers the insights needed to improve responsiveness and build supply chain resilience.

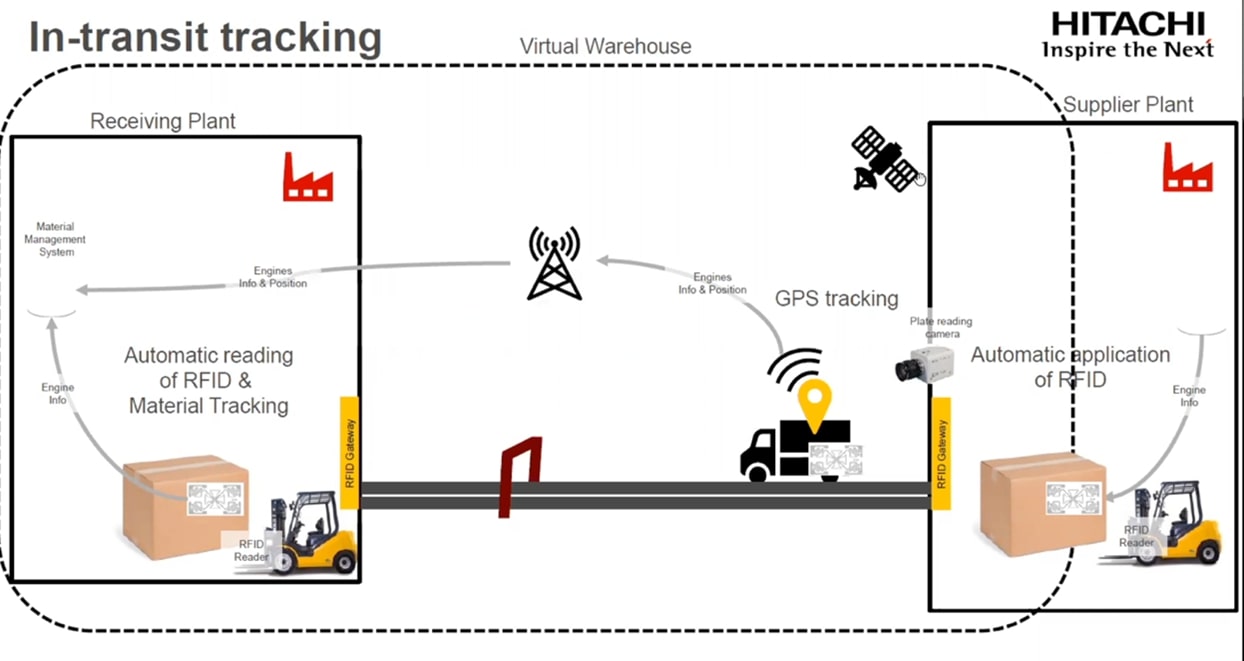

The goal is to evolve beyond what typical control towers offer, delivering the ability to autonomously alert or trigger workflows and provide decision support. Tracking and tracing key components and products all through the supply chain provides the core data for eventual autonomous management and control from supplier to the factory and the factory to the customer. In larger factories there is a growing need to apply the same level of tracking and tracing.

In a nutshell, a proven track and trace approach will allow you to use the same infrastructure to track multiple sources: materials, products in production, assets, and people. Specifically, track and trace solutions can:

Track and trace the order through the plant by mounting tags and dynamically associating the work order with the tags. This approach supports seamless tracking throughout production, even when the material moves into a different zone or is transferred to a different holding device or tag, or the source of data changes (RFID to GPS to BLE).

Manage events in the zone by monitoring how the movable assets go in and out of areas of production and shipping and sending alerts to managers as needed. For example, an alert is generated if an operator moves a specially calibrated tool from one zone to another, where it might disrupt the production process.

Make assets easy to configure and visualize. Typically, when managers and operators encounter a problem, they don’t want to get bogged down creating or waiting for code. They just want to fix it. A successful track and trace solution will operate via an intuitive administrative interface. For example, it may allow upload of JPG or PNG images of technical factory drawings to provide the image needed to designate zones (production line, workspace, machine) and associate appropriate tracker readers (RFID, BLE and QR).

Use cases for track and trace range from in-production and location or work-in-progress tracking to finished goods and in-transit tracking (see figure): The solution will produce alerts if your materials are in wrong location, inadequate or haven’t reached assembly station. It will report the absence of qualified people at specific station, receipt, and placement of a shipment, and how much of your product is on hand and ready to ship, as well as on the journey from factory to warehouse.

A caveat to the track and trace solution proposition is that your people must be ready for it. As you put the solution together it is important to involve your people in the journey so that they are ready for change.

The value proposition for the control tower with track and trace technologies is the extensiveness of the solution. Going beyond just visualization of the activity in your supply chain, track and trace enables the complex analytics involving materials, people, and assets, that produce actionable insights. It brings autonomous capabilities to tracking, identifying deviations, and predicting where issues may occur — disrupting any disruption in your manufacturing supply chain.

This story originally appeared on the Manufacturing Leadership Council blog.

Be sure to check out Insights for perspectives on the data-driven world.

Owen joined Hitachi Digital Services from Hitachi Vantara, where he led development of digital supply chain solutions. He has +25 years' experience in SCM and manufacturing, and has led digital transformation programs across a broad range of industries.