The Rapid Rise and Evolution of the Digital Twin

Digital twins have a well-established track record in the realm of high-end engineering, but the new technologies and trends will drive wider adoption and higher return on investment for digital twins. Jet-engine makers are veteran users of the technique to monitor performance and predict maintenance needs. For such complex and costly pieces of machinery, digital twins more than pay for themselves. Two new trends are underway that can make digital twins high-value propositions for more industries and applications:

As the types of IoT sensors grow, the information sensors provide becomes richer, more complete, and more valuable. “By combining data from several types of sensors, we essentially create new virtual sensors that measure combinations of factors that previously were not possible to monitor,” said Bjorn Andersson, senior director of global IoT marketing at Hitachi Vantara in this Datamation article.

For industrial and manufacturing operations, digital twins help train new engineers and anticipate how new technologies or process changes will impact operations. When done right, digital twins can bring new products to market faster and create safer, more efficient assets and lower cost operations.

For example, a digital twin of a building enables facilities management professionals to operate and maintain the structure to optimize energy utilization, employee safety, and office security. “The ubiquity of sensors, particularly video and lidar nowadays, means manufacturers, transportation, energy, commercial, and industrial organizations will move beyond smart assets to smart spaces and facilities,” Andersson explained.

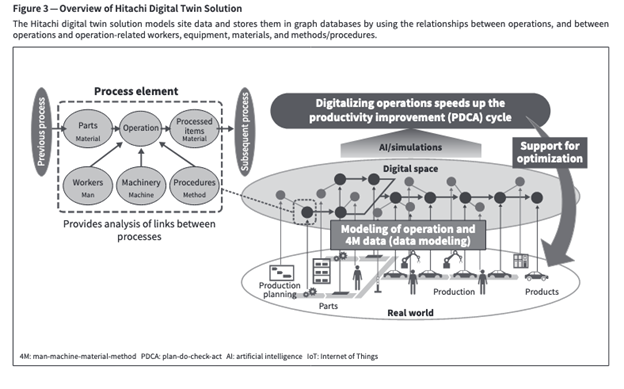

Wider access to design tools also means more people within organizations can create digital twins. In fact, an entire factory can be replicated in a digital twin, using Hitachi IoT technology. In this scenario, Lumada’s Digital Innovation Platform collects, refines, and stores vast amounts of data generated from a production site. The Hitachi Data Hub links data from the site to the digital twin. What-if scenarios can be run on the factory twin to explore the impact of specific changes on the productivity improvement cycle [see diagram].

Virtual sensors are combining inputs from multiple physical sensors to create metrics and values that either didn’t exist before or would have been too expensive to measure. By using existing sensor data and advanced algorithms, virtual sensors create inferred values to run new scenarios and simulations.

“New sensors will bring new funnels of data that create the pathway for full-scale digital twins, which can be transformed into actionable insights through computer vision and machine learning. We see this with the combination of lidar technology combined with traditional video and audio sources, which together can paint a more complete digital picture of facilities,” Andersson said.

Hitachi is collaborating with the Amazon Web Services (AWS) IoT team, for example, to offer industrial solutions. The partnership enables industrial companies to capture IoT data about processes and assets and migrate the data to a structured data store at the edge and in the cloud. There, the data is analyzed to generate actionable insights to increase efficiencies, reduce costs, and improve profitability in their industrial operations.

Subaru of Indiana Automotive, Inc. is using the Lumada-AWS solution in its manufacturing operations. "The integration between AWS and Hitachi Vantara gives us a strong digital platform that adds scale and velocity as we advance through our digital and cloud journey," said Bob Wu, vice-president of production control and information systems at Subaru of Indiana.

Looking ahead, IDC predicts digital twin data will be shared across industry ecosystems, creating tighter bonds between supply chain partners. “By 2025, 80% of industry ecosystem participants will leverage their own product, asset, and process digital twins to share data and insight with other participants,” according to IDC’s December 2021 FutureScape.

One way or another, digital twins are becoming ubiquitous and the knowledge they provide is enabling a broad range of industries to achieve new levels of innovation and productivity.

Check out more great stories on Insights.

Specializing in Industrial IoT, digital transformation, Industry 4.0 operating models, supply chain and asset management, manufacturing ops and predictive maintenance, Sid helps customers create smart, connected factories and intelligent products.