The Reason You Need To Go Digital...Now

You’ve probably heard about new technologies that are reshaping the way we work and live, like 5G and the Internet of Things (IoT), but have you noticed how data is the common denominator among those technologies? The lines between digital and physical worlds are seemingly blurring at the speed of 178 terabits a second, the world’s fastest data transmission rate[1]

Understanding how to converge the physical world (sensors, machines, processes, places, and people) with the digital world (software, platforms, and analytics) will help you create meaningful insights that can revolutionize your business model and operations.

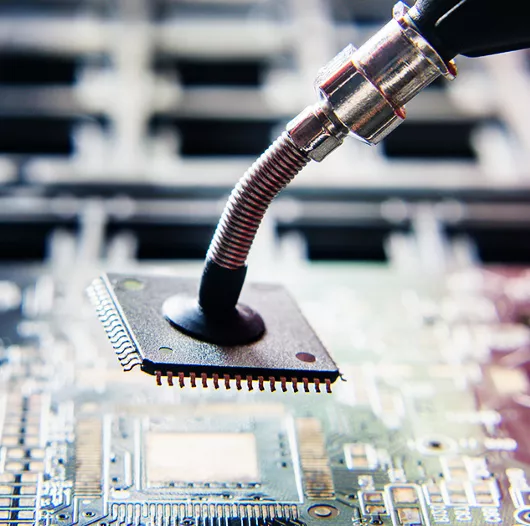

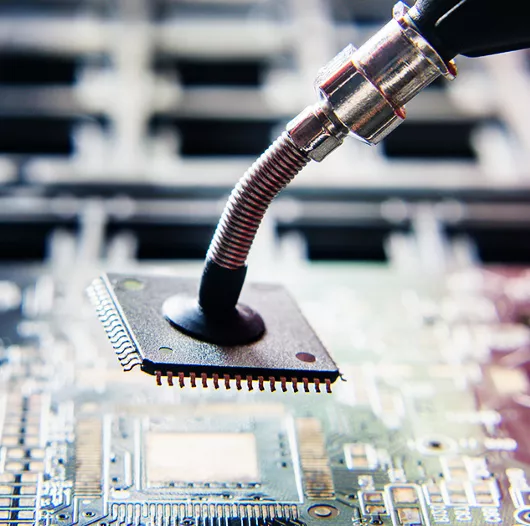

The miniaturization of parts has increased the viability of putting sensors on virtually everything, allowing machines of all types to connect and share data interchangeably. The proliferation of smartphones and other devices with ubiquitous wireless communication networks like 5G or low earth orbit (LEO) communication satellites has radicalized what it means to be mobile and connected. The ability to access resources on-demand and consume data in the cloud or on the edge has granted companies unimaginable computing power wherever and whenever they need it.

The physical-digital intersection is enabling exponential change toward a more connected, intelligent world. For instance, Low-Earth-Orbit satellite constellations will soon bring high-speed internet access to remote areas. Elon Musk’s satellite internet company Starlink, best known for its initial beta service, has about 10,000 users and exceeds 200 Mbps in tests.[2] OneWeb, Jeff Bezos’ communications company, is powered by LEO and has already launched 146 satellites.[3]

Worldwide spending on the technologies and services that enable the digital transformation of business practices, products, and organizations is forecasted to reach $1.97 trillion in 2022.[4] The digitalization wave is an unstoppable reality. You either prepare and ride the successive waves of digital technologies or risk being whipped out by the inevitable disruption

Technological advances in sensors and connectivity drive digitalization, miniaturization of equipment, more available bandwidth, and more effortless connectivity with private or public 5G – at a lower cost. If you consider the ever-expanding capabilities that stem from analyzing the data your company can gather by using AI, you’ll quickly realize the tremendous impact it will have on the way you run your business.

You can take part even if your corporate data exists mostly on paper. Ripcord, a document digitization company, processes over one billion pages per year for their clients, using robotics, sensors, and software automation to create a digital twin of an organization’s documents. They leverage machine learning algorithms to use deep learning on a large and ever-growing dataset, enabling high accuracy OCR, to intelligently capture content and metadata to build digitized repositories. From meeting compliance and security policies to enriching data to make it searchable and actionable, companies can reap incredible benefits from digitizing their paper records.

The trend toward digitalization impacts every industry, but a noteworthy benefactor is the industrial sector. According to Gartner, installed IoT endpoints for manufacturing and natural resources industries are forecast to grow to 1.9 billion units in 2028.[5]

While the most obvious use cases in industrial IoT illustrate how manufacturers help improve customer service by enabling leaders to better understand customer needs, more mature organizations create information-based products such as providing visibility and analytics for better asset usage.

Penske‘s, a transportation services company, the logistical supply chain was once based on preplanned routes for shipments from suppliers to its plants. However, when production schedules starting experiencing fluctuations, too many trucks were underutilized and costs started to spike. By using predictive analytics to forecast the demand for truck space, Penske was able to optimize the route plan in line with the manufacturer’s changing production schedules. Another efficiency driver for Penske can be seen with the use of telematic equipment on their trucks for their subsidiary company, Penske Truck Leasing. They used IoT sensors to continuously monitor vehicle performance by tracking the location and temperature of goods in transit.[6]

“Winning in the digital era is defined by the ability to sense and respond to changing customer, constituent, market and political conditions at “digital speed.” The winners and losers in the digital era are not just those that can scale their offerings, but those who can sense and respond the fastest” [7] - Gartner Information Technology Research

As you embark on your digitalization journey, you’ll realize that your pace of progression increases dramatically. The more data you collect, the faster you’ll learn to analyze it and determine the next step of preparedness for advanced levels. As these levels build on each other to compound impact, you will gradually outpace your competition to reap the benefits of setting your tempo for your business’s next phase. This kind of agility allows you to capture new opportunities and releases you from avoidable pitfalls. A prepared business is an efficient business that controls costs and maximizes profits.

On the other hand, catching up will become virtually impossible if you miss the ship and fail to embark. There’s a new digital divide that’s forming. Gone are the days of gradual improvement methods; a couple of percentage points better in individual turns aren’t going to cut it, especially if the time between turns is long. Nothing should keep organizations from navigating towards success in a data-driven, digital world, not even a global pandemic.

The most efficient way to compete in a digitalized world is to find a guide who can help you navigate IT and OT complexities. An advisor that understands where you stand on digitization and can help you lay the digital foundation for implementing the technological foundations you need to transform your business into the digital horizon.

Despite the disruptive impacts of COVID-19, a recent Gartner survey[8] reveals that 47% of organizations will increase investments in IoT. The survey also showed that 27% of companies plan to use digital twins for autonomous equipment, robots, or vehicles. By 2023, Gartner expects that in conjunction with at least one IoT project, one-third of companies will also implement artificial intelligence.

Hitachi is in a unique position to help you intersect your physical coordinates with your aspirational digital coordinates. We have more than a century of experience as a large industrial company in the physical world, and more than half a century of experience as a leader in the cyber world. Hitachi has worked with a variety of industrial customers to improve worker productivity and safety, as well as asset efficiency and processes, without “ripping and replacing” the existing machinery or digital systems. For example, by integrating video analytics and 3D lidar we created tremendous opportunities for our clients to measure what was previously unmeasurable, and thereby providing more data for managers, as well as experienced and new workers. These technologies help to reduce disruption and retraining costs while minimizing the financial impact of innovating.

Not everyone is setting sail from the same port, nor will everyone’s journey follow the same course. However, digital adoption will get you on course to reach your new digitally-enabled destination.

To learn how to optimize your manufacturing operations by implementing solutions that deliver improved resilience and increased agility, read our recently published press release around Lumada Manufacturing Insights, Hitachi Vantara’s enhanced suite of IoT products.

Get a front-row seat to the future of Social Innovation. Join us at the virtual Hitachi Social Innovation Forum on May 25-27. Register here.

[1] University College London. “eNw Internet Speed World Record: 178 Terabits a Second.” SciTechDaily, Royal Academy of Engineering, The Royal Society Research grant, and the EPSRC program grant TRANSNET, https://scitechdaily.com/new-internet-speed-world-record-178-terabits-a-second/.

[2] Khan, Imad. “Elon Musk’s Starlink internet exceeds 200 Mbps in new tests.” Tom’s Guide, 4 April 2021, https://www.tomsguide.com/news/starlink-internet-just-hit-200-mbps-heres-the-proof.

[3] OneWeb. “OneWeb Launch Programme.” OneWeb Launches, 2021, https://www.oneweb.world/launches. March 2021.

[4] Simpson, Craig, et al. “The Worldwide Digital Transformation Spending Guide.” IDC Trackers, IDC, May 2020, https://www.idc.com/tracker/showproductinfo.jsp?containerId=IDC_P32575.

[5] Tohamy, Noha. “Hype Cycle for Supply Chain Strategy, 2020.” Gartner Research, Gartner, 6 August 2020, https://www.gartner.com/en/documents/3988513-hype-cycle-for-supply-chain-strategy-2020.

[6] Penske. “Responses to Rising Costs in Manufacturing.” Industrial Manufacturing, Penske, 2020, https://www.penskelogistics.com/industries/industrial-manufacturing/manufacturing-costs.

[7] Hill, Janelle, et al. “Follow 7 Principles to Redesign Your Operating Model Before It Fails.” Gartner, 14 October 2020, https://www.gartner.com/en/documents/3991723/follow-7-principles-to-redesign-your-operating-model-bef

[8] Xiang, Milly, and Benoit Lheureux. “Survey Analysis: COVID-19 Use Cases Are Driving IoT Adoption, Powered by Innovations Like AI and Digital Twins.” Gartner Research, Gartner, 2 February 2021, https://www.gartner.com/en/documents/3996326-summary-translation-localization-survey-analysis-covid-1.

Bjorn has worked in technology development, product management and marketing for +25 years, with a focus on sustainability, digital transformation, analytics, visualization, HPC and IoT. Today, he provides strategic leadership for select industry practices at Hitachi Vantara.